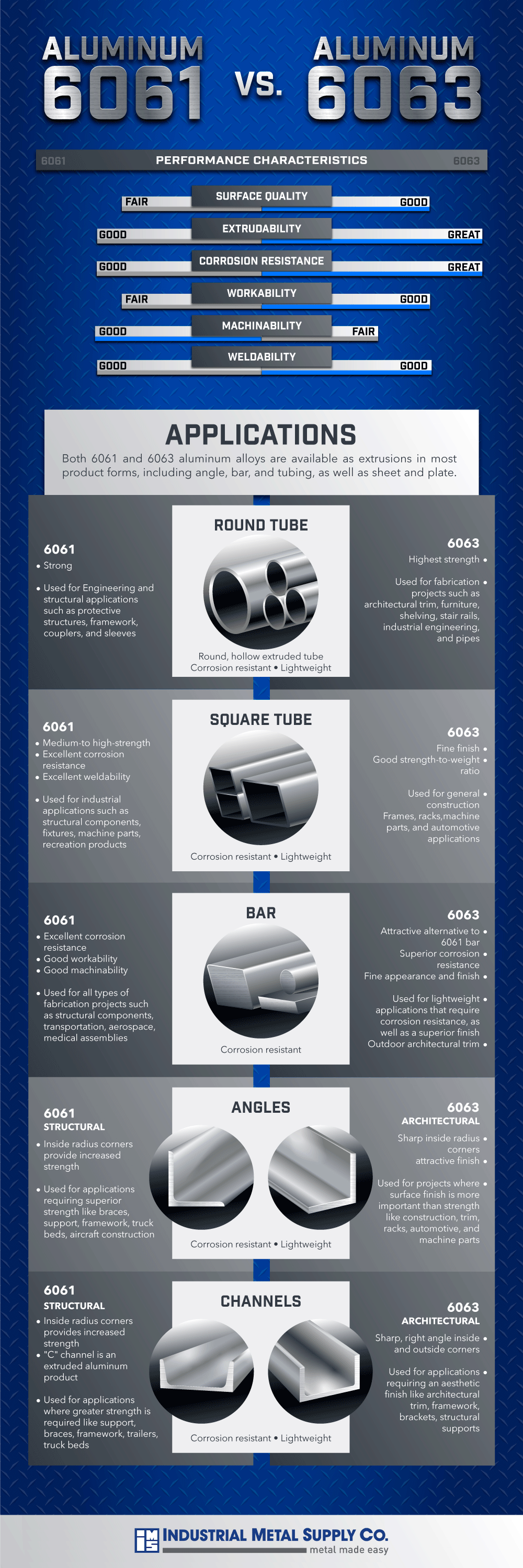

Aluminum 6061 and Aluminum 6063 are similar in composition and mechanical properties, and both are popular for extrusions. Both alloys contain magnesium for increased strength and silicon to reduce the melting temperature. Alloy 6061, or structural aluminum, comes in two variations, or tempers, T4 and T6, which have slightly different properties caused by processing after extrusion. Commons uses include transportation components, recreation products, machinery and equipment, and consumer durables. Alloy 6063, or architectural aluminum, can be soft anodized to create an aesthetically pleasing, colored finish for visual architectural and building applications such as window frames, door frames, roofs, and sign frames since high strength is not the most important factor. It is also used for electrical components and conduit, pipe and tube for irrigation systems, architectural & building products, railings, furniture, appliances, boats, and motor vehicles. For applications that require higher strength, 6061 or 6082 are typically used. 6063 is primarily used for applications that are exposed because it suffers weather better than 6061, making it more corrosion resistant. Their slightly different characteristics make each one a better choice for different applications.

6061 and 6063 aluminum alloys come in various product forms, including angle, bar, round tubing, square tubing, and channels. This infographic will help you choose between aluminum alloys 6061 vs. 6063.

Our Locations

Filter your product specifications, choose product view options,

download our catalog, and create a project list.